Top Induction Heaters for Bearing Heating in Mumbai, India

VEL Innovative Technologies is a trusted name in providing induction heaters for bearing heating in Mumbai, India. Our VEL/BH series is designed to offer precise and efficient heating solutions for bearing installation, ensuring a smooth and secure process. Utilizing advanced induction heating technology, our machines deliver uniform and controlled heating, making them ideal for industries requiring high-performance bearing heating solutions. As leading induction heaters for bearing heating in Mumbai, India, we offer reliable and easy-to-use equipment that ensures optimal results every time. The VEL/BH series is built to meet the specific needs of industries requiring efficient and precise bearing heating for installation purposes.

Choose VEL Innovative Technologies for the best induction heaters for bearing heating in Mumbai, India, and experience superior quality and performance in every application. For More Information Pls Contact Us or Call Us +91 8104163453 or Email Us : mail@velinnovative.com sales@velinnovative.com

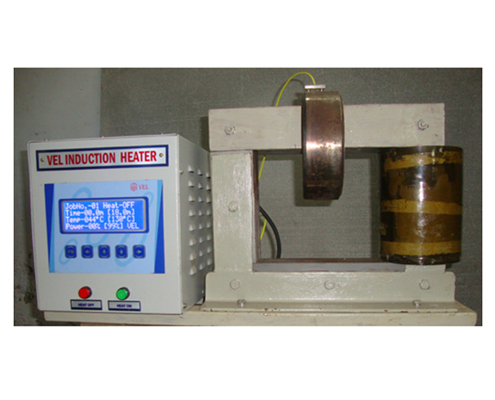

Induction Heaters for Bearing Heating (VEL BH Series)

VEL BH series is a comprehensive range of Microcontroller based Electronic Control, Induction Heater, specifically designed and manufactured for mounting of shrink fitting components such as Bearings, inner races, gears, pinons, couplings, etc.

Related Services:

Induction Bearing Heater, Portable Bearing Induction Heater, Induction Heaters for Bearing Heating, Induction Bearing Heater at best Prices, Induction Bar End Heater, Induction Billet Heater, Billet Heating & Billet Induction heater.

Standard Features of Induction Heaters for Bearing Heating Manufactured by Vel Innovation Technologies Pvt Ltd. Mumbai, India

- Rugged and mobile construction

- Very Fast and efficient heating

- Heating of max bearing weights in less than 15 minutes

Our Machines Supplied

|

|

|

|

|

|

|

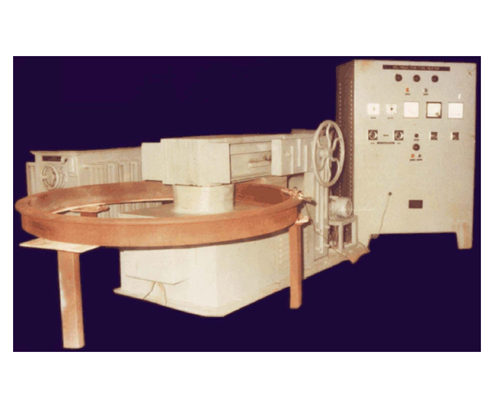

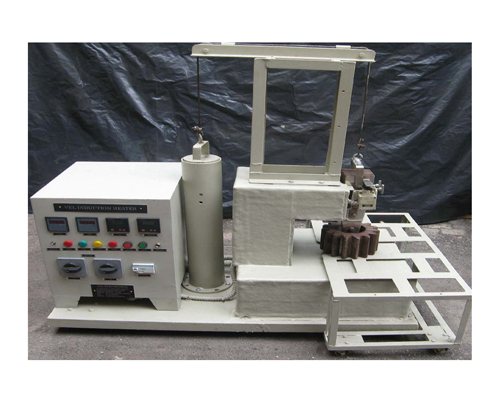

| Model No. | VEL/BH3 | VEL/BH8 | VEL/BH10 | VEL/BH13 | VEL/BH16 | VEL/BH25 |

| Technology | Microcontroller based Electronic Control, Induction Heater, specifically designed and manufactured for mounting of shrink fitting components such as Bearings, inner races, gears, pinons, couplings, etc. | |||||

| Bore Diameter Range | 20 to 300mm | 30 to 400mm | 70 to 600 mm | 100 to 1000mm | 55 to 600 mm | 100 to 1000mm |

| Max Bearing Weight | 40 kg (88 lb) | 120 kg (264 lb) | 300 kg (662 lb) | 1200 kg (2600 lb) | 300 kg (662 lb) | 1200 kg (2600 lb) |

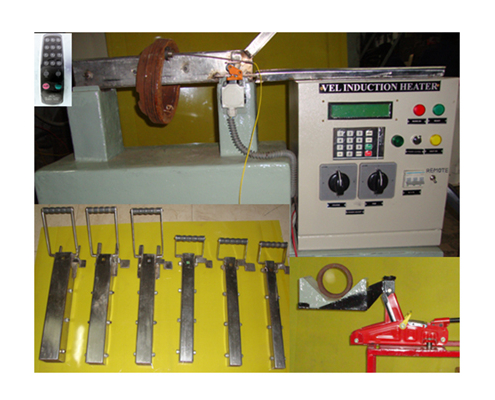

| Coil & Yoke details | Single coil, horizontal swing arm yoke | Single coil, horizontal swing arm yoke | Single coil, vertical moving yoke | Single coil, vertical moving yoke (Motorized/ Manual) | Dual coil, horizontal rolling arm yoke | Dual coil, vertical moving yoke (Motorized/ Manual) |

| Job position axis | Vertical to the ground | Vertical to the ground | Vertical to the ground | Vertical to the ground | Horizontal to the ground | Vertical to the ground |

| Incoming Voltage | 230V, 1phase, 50Hz. | 415V, 50Hz, 3 Phase AC Supply | ||||

| Output Power | 2-3KVA | 6- 8KVA | 10- 12 KVA | 25 – 40 KVA | 14 – 16KVA | 25 – 40 kVA |

| Operational parameters | Time (0-99mins), Temperature (0 to 250°C, in step of 1°C), Power (0-100%) | |||||

| Temperature control | 25 – 250 +/- 1°C | |||||

| Memory Backup | To set & save all the operational parameters for different jobs (99 no. of jobs) in rewritable memory (EEPROM) of the microcontroller | |||||

| MMI | Man Machine Interface is 4-line alpha numeric LCD display. The LCD Displays all set, operational and trip parameters etc. Five functional keys to set & save the operational parameter | |||||

| Safety Interlocks | Soft start to avoid rush of surge current at time of switching

Over temperature of coil trip Current control & overload trip |

|||||

| Operating Area | 100 x 135 mm | 155 x 205 mm | 450 x 625 mm | 230 x 675 mm | 245 x 330 mm | 230 x 715 mm |

| Residual Magnetism | <2A/cm, Auto De – Magnetization | |||||

| Yoke size to suit bearing diameter | 14x14x215mm

28x28x215mm 45x45x215mm |

20 x 20 x350 mm

28 x 28 x 350 mm 45 x 45 x 350 mm 65 x 65 x 350 mm |

50 x 50mm

85 x 85mm |

70 x 70 mm

80 x 80mm 100 x 100mm |

40 x 40 x 500mm

60 x 60 x 500mm |

70 x 70 mm

80 x 80mm 100 x 100mm |

Note:

- We provide standard size of yoke as per industry standards. For any specific requirement, we also provide custom size yokes.

- For bearing weights more than 1200 kgs, we customize the product as per customer’s requirement and provide larger induction heaters.

- We also customize and manufacture bearing heaters as per client’s requirement.

Download Catalogue

| Accessories | Description & Features |

| Cooling System | 1) Refrigerant Chiller Unit 2) Cooling Tower with plate – type heat exchanger |

| Fixtures | 1) Mobile Hanging Assembly for Hand Held Transformer. 2) Manual / Motorized Rotary Fixtures (Horizontal / Vertical ) 3) XYZ Slide Fixture for Fixed Transformer |